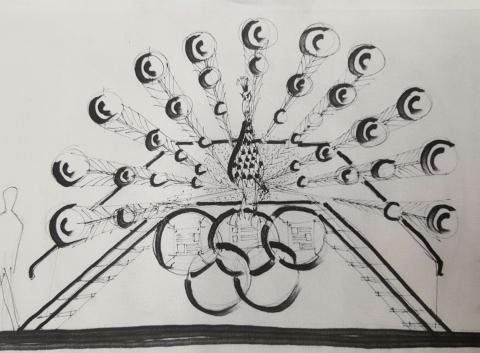

The ICTP2017 Peacock, designed by Cambridge artist David Carmichael, celebrates the technologies of metal forming. It has been created for the 12th International Conference on Technology of Plasticity, held in the UK for the first time, in Cambridge, in September 2017. The peacock was made with a combination of established techniques and new processes developed in the Cambridge University Engineering Department and was unveiled at our spectacular opening public lecture.

Head and small feather eyes: Incremental sheet forming

A smooth indenter moves across a sheet under computer control to create unique parts. Research in Cambridge has revealed that this process creates a through-thickness shearing which increases forming limits, and with a stereovision camera has led to the first application of closed-loop control of geometry in sheet forming.

Large feather eyes: Mandrel free spinning

Large feather eyes: Mandrel free spinning

This process, invented in Cambridge and now embodied in an industrial prototype by Primetals Ltd, replaces the mandrel used in conventional spinning with three computer-controlled rollers. The seven variant eyes of the Peacock’s feathers could therefore be made by the same process without any dedicated tooling.

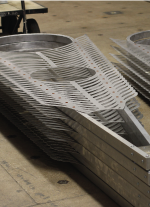

Feathers: Sheet rolling

Feathers: Sheet rolling

Invented by Leonardo da Vinci, the rolling mill is the most universal metal forming process, used to control sheet thickness, residual stress and microstructure with extraordinary precision.

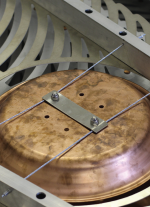

Rings: flexible ring-rolling

Rings: flexible ring-rolling

Ring rolling is used to expand and shape metal rings with a rectangular cross-section. The new process invented in Cambridge allows computer-controlled shaping of the rings with no material removal. The cross-sections of these rings spell out the conference acronym, ICTP, and were made with no scrap at all.

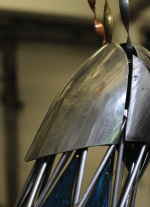

Back of head: English wheel

Back of head: English wheel

Before widespread adoption of the double-action press, car-body parts were shaped with this simple process. Two opposed rollers force a local thinning of the sheet, causing localised spreading and bulging.

Feather-ribs: Extrusion

Feather-ribs: Extrusion

Aluminium extrusion is widely used to create long profiles with constant cross-sections. The semi-circular ends of the ribs were welded.

Rivets: Cold forging

Rivets: Cold forging

396 copper rivets were used to assemble the feathers, hammered between two dies to create a stiff joint between the separate components.

Body: Three roll bending

Body: Three roll bending

Three-roll bending, with a central roll offset from two support-rollers, was used to shape the wires and feathers with increasing curvature.

Beak: Stamping

Beak: Stamping

The two halves of the beak were stamped between dedicated male and female dies, squeezed in a hydraulic press and then welded.

Suspension wires: Drawing

Suspension wires: Drawing

Each feather-eye is suspended on wires, which were manufactured by twisting together 49 high tensile steel strands, each of which was drawn down from rod, through a sequence of ever smaller dies.

Eyes: Heat treatment

Eyes: Heat treatment

The stainless steel eyes were locally heated at the iris to around 600°C and then allowed to cool in air.

| David Carmichael | Artist |

| Dr Adam Nagy | Engineering design and assembly |

| Tom Andersson | Prototype feather design |

| Iacopo Russo | Large feather eyes design and manufacture |

| Katie Daehn | Body feather colouring, body and crown manufacture |

| José Azevedo | Body structure, head and crown design and manufacture |

| Dr Cyrille Dunant | Small feather eye manufacture |

| Dr Rick Lupton | Small feather eye manufacture |

| Dr Christopher Cleaver | Ring design and manufacture |

| Philippa Horton | Construction management, body and feather manufacture |

| Michal Drewniok | Bridge |

| Mark Vining | Welding and Fabrication |

| Kevin Ablett | Sheet Metal |

| Kynan Wright | Apprentice Welding and Fabrication |

| Matt Stewart | Apprentice Machinist |

| Steve Robinson | Senior Machinist |

| Alan Jackson | Senior Machinist |

| Richard Boothroyd | Machinist |

| Martin Touhey | Assembly |

| Alistair Ross | Workshop Manager |

| Professor Julian M Allwood FREng |